Lithium-ion battery

Nokia Li-ion battery for powering a mobile phone |

|

| specific energy | (0.36-0.90 MJ/kg) |

|---|---|

| energy density | (0.90-1.30 MJ/L) |

| specific power | ~250-~340 W/kg[1] |

| Charge/discharge efficiency | 80-90%[2] |

| Energy/consumer-price | 1.5 Wh/US$[3] |

| Self-discharge rate | 8% at 21 °C 15% at 40 °C 31% at 60 °C (per month)[4] |

| Cycle durability |

400-1200 cycles [5] |

| Nominal cell voltage | 3.6 / 3.7 V |

A lithium-ion battery (sometimes Li-ion battery or LIB) is a family of rechargeable battery types in which lithium ions move from the negative electrode to the positive electrode during discharge, and back when charging. Chemistry, performance, cost, and safety characteristics vary across LIB types. Unlike lithium primary batteries (which are disposable), lithium-ion cells use an intercalated lithium compound as the electrode material instead of metallic lithium.

Lithium-ion batteries are common in consumer electronics. They are one of the most popular for portable electronics, with one of the best energy-to-weight ratios, no memory effect, and a slow loss of charge when not in use. Beyond consumer electronics, LIBs are growing in popularity for military, electric vehicle, and aerospace applications due to their high energy density.[6] Research is yielding a stream of improvements to traditional LIB technology, focusing on energy density, durability, cost, and safety.

Contents |

Charge and discharge

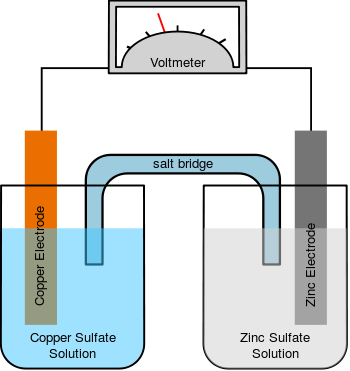

During discharge, lithium ions Li+ carry the current from the negative to the positive electrode, through the non-aqueous electrolyte and separator diaphragm.[7]

During charging, an external electrical power source (the charging circuit) applies a higher voltage (but of the same polarity) than that produced by the battery, forcing the current to pass in the reverse direction. The lithium ions then migrate from the positive to the negative electrode, where they become embedded in the porous electrode material in a process known as intercalation.

Construction

The three primary functional components of a lithium-ion battery are the anode, cathode, and electrolyte. The anode of a conventional lithium-ion cell is made from carbon, the cathode is a metal oxide, and the electrolyte is a lithium salt in an organic solvent.[8]

The most commercially popular anode material is graphite. The cathode is generally one of three materials: a layered oxide (such as lithium cobalt oxide), a polyanion (such as lithium iron phosphate), or a spinel (such as lithium manganese oxide).[9]

The electrolyte is typically a mixture of organic carbonates such as ethylene carbonate or diethyl carbonate containing complexes of lithium ions.[10] These non-aqueous electrolytes generally use non-coordinating anion salts such as lithium hexafluorophosphate (LiPF6), lithium hexafluoroarsenate monohydrate (LiAsF6), lithium perchlorate (LiClO4), lithium tetrafluoroborate (LiBF4), and lithium triflate (LiCF3SO3).

Depending on materials choices, the voltage, capacity, life, and safety of a lithium-ion battery can change dramatically. Recently, novel architectures using nanotechnology have been employed to improve performance.

Pure lithium is very reactive. It reacts vigorously with water to form lithium hydroxide and hydrogen gas is liberated. Thus a non-aqueous electrolyte is typically used, and a sealed container rigidly excludes water from the battery pack.

History

Lithium-ion batteries were first proposed by M.S. Whittingham at Binghamton University, at Exxon, in the 1970s.[11] Whittingham used titanium(II) sulfide as the cathode and lithium metal as the anode.

The electrochemical properties of lithium intercalation in graphite were first discovered in 1980 by Rachid Yazami et al., at the Grenoble Institute of Technology (INPG) and French National Centre for Scientific Research (CNRS) in France. They showed the reversible intercalation of lithium into graphite in a lithium/polymer electrolyte/graphite half cell. Their work was published in 1982 and 1983.[12][13] It covered both thermodynamics (staging) and kinetics (diffusion) together with reversibility.

Primary lithium batteries in which the anode is made from metallic lithium pose safety issues. As a result, lithium-ion batteries were developed in which both anode and cathode are made of a material containing lithium ions. In 1981, Bell Labs developed a workable graphite anode[14] to provide an alternative to the lithium metal battery. Following groundbreaking cathode research by a team led by John Goodenough,[15] in 1991 Sony released the first commercial lithium-ion battery. Their cells used layered oxide chemistry, specifically lithium cobalt oxide and revolutionized consumer electronics.

In 1983, Michael Thackeray, Goodenough, and coworkers identified manganese spinel as a cathode material.[16] Spinel showed great promise, given low-cost, good electronic and lithium ion conductivity, and three-dimensional structure which gives it good structural stability. Although pure manganese spinel fades with cycling, this can be overcome with chemical modification of the material.[17] Manganese spinel is currently used in commercial cells.[18]

In 1989, Goodenough and Arumugam Manthiram of the University of Texas at Austin showed that cathodes containing polyanions, e.g. sulfates, produce higher voltages than oxides due to the inductive effect of the polyanion.[19]

In 1996, Goodenough, Akshaya Padhi and coworkers identified lithium iron phosphate (LiFePO4) and other phospho-olivines (lithium metal phosphates with olivine structure) as cathode materials.[20]

In 2002, Yet-Ming Chiang and his group at MIT showed a substantial improvement in the performance of lithium batteries by boosting the material's conductivity by doping it with aluminum, niobium and zirconium. The exact mechanism causing the increase became the subject of a heated debate.[21]

In 2004, Chiang again increased performance by utilizing iron-phosphate particles of less than 100 nanometers in diameter. This decreased particle density by almost one hundredfold, increased the cathode's surface area and improved capacity and performance. Commercialization led to a competitive market and a patent infringement battle between Chiang and Goodenough.[21]

Electrochemistry

The three participants in the electrochemical reactions in a lithium-ion battery are the anode, cathode, and electrolyte.

Both the anode and cathode are materials into which, and from which, lithium can migrate. During insertion (or intercalation ) lithium moves into the electrode. During the reverse process, extraction (or deintercalation) lithium moves back out. When a lithium-based cell is discharging, the lithium is extracted from the anode and inserted into the cathode. When the cell is charging, the reverse occurs.

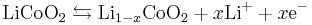

Useful work can only be extracted if electrons flow through a closed external circuit. The following equations are in units of moles, making it possible to use the coefficient  . The cathode half-reaction (with charging being forwards) is: [22]

. The cathode half-reaction (with charging being forwards) is: [22]

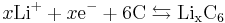

The anode half reaction is:

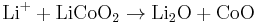

The overall reaction has its limits. Overdischarge supersaturates lithium cobalt oxide, leading to the production of lithium oxide,[23] possibly by the following irreversible reaction:

Overcharge up to 5.2 Volts leads to the synthesis of cobalt(IV) oxide, as evidenced by x-ray diffraction[24]

In a lithium-ion battery the lithium ions are transported to and from the cathode or anode, with the transition metal, cobalt (Co), in  being oxidized from Co3+ to Co4+ during charging, and reduced from Co4+ to Co3+ during discharge.

being oxidized from Co3+ to Co4+ during charging, and reduced from Co4+ to Co3+ during discharge.

Cathodes

| Cathode Material | Average Voltage | Gravimetric Capacity | Gravimetric Energy |

|---|---|---|---|

| LiCoO2 | 3.7 V | 140 mA·h/g | 0.518 kW·h/kg |

| LiMn2O4 | 4.0 V | 100 mA·h/g | 0.400 kW·h/kg |

| LiNiO2 | 3.5 V | 180 mA·h/g | 0.630 kW·h/kg |

| LiFePO4 | 3.3 V | 150 mA·h/g | 0.495 kW·h/kg |

| Li2FePO4F | 3.6 V | 115 mA·h/g | 0.414 kW·h/kg |

| LiCo1/3Ni1/3Mn1/3O2 | 3.6 V | 160 mA·h/g | 0.576 kW·h/kg |

| Li(LiaNixMnyCoz)O2 | 4.2 V | 220 mA·h/g | 0.920 kW·h/kg |

Anodes

| Anode Material | Average Voltage | Gravimetric Capacity | Gravimetric Energy |

|---|---|---|---|

| Graphite (LiC6) | 0.1-0.2 V | 372 mA·h/g | 0.0372-0.0744 kW·h/kg |

| Hard Carbon (LiC6) | ? V | ? mA·h/g | ? kW·h/kg |

| Titanate (Li4Ti5O12) | 1-2 V | 160 mA·h/g | 0.16-0.32 kW·h/kg |

| Si (Li4.4Si)[25] | 0.5-1 V | 4212 mA·h/g | 2.106-4.212 kW·h/kg |

| Ge (Li4.4Ge)[26] | 0.7-1.2 V | 1624 mA·h/g | 1.137-1.949 kW·h/kg |

Electrolytes

The cell voltages given in the Electrochemistry section are larger than the potential at which aqueous solutions can electrolyze, in addition lithium is highly reactive to water, therefore, nonaqueous or aprotic solutions are used.

Liquid electrolytes in lithium-ion batteries consist of lithium salts, such as LiPF6, LiBF4 or LiClO4 in an organic solvent, such as ethylene carbonate, dimethyl carbonate, and diethyl carbonate. A liquid electrolyte conducts lithium ions, acting as a carrier between the cathode and the anode when a battery passes an electric current through an external circuit. Typical conductivities of liquid electrolyte at room temperature (20 °C (68 °F)) are in the range of 10 mS/cm (1 S/m), increasing by approximately 30–40% at 40 °C (104 °F) and decreasing by a slightly smaller amount at 0 °C (32 °F)[27]

Unfortunately, organic solvents easily decompose on anodes during charging. However, when appropriate organic solvents are used as the electrolyte, the solvent decomposes on initial charging and forms a solid layer called the solid electrolyte interphase (SEI),[28] which is electrically insulating yet provides sufficient ionic conductivity. The interphase prevents decomposition of the electrolyte after the second charge. For example, ethylene carbonate is decomposed at a relatively high voltage, 0.7 V vs. lithium, and forms a dense and stable interface.

Advantages and disadvantages

Note that both advantages and disadvantages depend on the materials and design that make up the battery. This summary reflects older designs that use carbon anode, metal oxide cathodes, and lithium salt in an organic solvent for the electrolyte.

Advantages

- Wide variety of shapes and sizes efficiently fitting the devices they power.

- Much lighter than other energy-equivalent secondary batteries.[29]

- High open circuit voltage in comparison to aqueous batteries (such as lead acid, nickel-metal hydride and nickel-cadmium).[30] This is beneficial because it increases the amount of power that can be transferred at a lower rate of current.

- No memory effect.

- Self-discharge rate of approximately 5-10% per month, compared to over 30% per month in common nickel metal hydride batteries, approximately 1.25% per month for Low Self-Discharge NiMH batteries and 10% per month in nickel-cadmium batteries.[31] According to one manufacturer, lithium-ion cells (and, accordingly, "dumb" lithium-ion batteries) do not have any self-discharge in the usual meaning of this word.[22] What looks like a self-discharge in these batteries is a permanent loss of capacity (see Disadvantages). On the other hand, "smart" lithium-ion batteries do self-discharge, due to the drain of the built-in voltage monitoring circuit.

Disadvantages

Shelf life

- Charging forms deposits inside the electrolyte that inhibit ion transport. Over time, the cell's capacity diminishes. The increase in internal resistance reduces the cell's ability to deliver current. This problem is more pronounced in high-current applications. The decrease means that older batteries do not charge as much as new ones (charging time required decreases proportionally).

- High charge levels and elevated temperatures (whether from charging or ambient air) hasten capacity loss.[32][33] Charging heat is caused by the carbon anode (typically replaced with lithium titanate which drastically reduces damage from charging, including expansion and other factors).[34]

- A unit that is full most of the time at 25 °C (77 °F) irreversibly loses approximately 20% capacity per year. Poor ventilation may increase temperatures, further shortening battery life. Loss rates vary by temperature: 6% loss at 0 °C (32 °F), 20% at 25 °C (77 °F), and 35% at 40 °C (104 °F). When stored at 40%–60% charge level, the capacity loss is reduced to 2%, 4%, and 15%, respectively.[35]

Internal resistance

- The internal resistance of lithium-ion batteries is high compared to other rechargeable chemistries such as nickel-metal hydride and nickel-cadmium. Internal resistance increases with both cycling and age.[33][36] Rising internal resistance causes the voltage at the terminals to drop under load, which reduces the maximum current draw. Eventually increasing resistance means that the battery can no longer operate for an adequate period.

- To power larger devices, such as electric cars, connecting many small batteries in a parallel circuit is more efficient than connecting a single large battery.[37]

Safety requirements

Li-ion batteries are not as durable as nickel metal hydride or nickel-cadmium designs, and can be dangerous if mistreated. They may suffer thermal runaway and cell rupture if overheated or overcharged.[38] In extreme cases, these effects may be described as "explosive." Furthermore, overdischarge can irreversibly damage a battery. To reduce these risks, batteries generally contain a small circuit that shuts down when the battery moves outside the safe range of 3–4.2 V.[22][31] When stored for long periods, however, the small current drawn by the protection circuitry itself may drain the battery; normal chargers are then ineffective. More sophisticated battery analyzers can recharge deeply discharged cells by slow-charging them to first reactivate the safety circuit and allow the battery to accept charge. Overdischarge can short-circuit the cell, in which case recharging can be unsafe.[39]

Other safety features are required:[22]

- shut-down separator (for overtemperature)

- tear-away tab (for internal pressure)

- vent (pressure relief)

- thermal interrupt (overcurrent/overcharging)

These devices occupy useful space inside the cells, reduce their reliability; ,and irreversibly disable the cell when activated. They are required because the anode produces heat during use, while the cathode may produce oxygen. These devices and improved electrode designs reduce/eliminate the risk of fire or explosion.

These safety features increase costs compared to nickel metal hydride batteries, which require only a hydrogen/oxygen recombination device (preventing damage due to mild overcharging) and a back-up pressure valve.[31]

Many types of lithium-ion cell cannot be charged safely below 0°C.

Product recalls

About 1% of lithium-ion batteries are recalled over safety concerns.[40]

Specifications and design

- Specific energy density: 150 to 250 W·h/kg (540 to 720 kJ/kg)[1]

- Volumetric energy density: 250 to 530 W·h/l (900 to 1900 J/cm³)

- Specific power density: 300 to 1500 W/kg (@ 20 seconds and 285 W·h/l)[1]

Because lithium-ion batteries can have a variety of cathode and anode materials, the energy density and voltage vary accordingly.

Lithium-ion batteries with a lithium iron phosphate cathode and graphite anode have a nominal open-circuit voltage of 3.2 V and a typical charging voltage of 3.6 V. Lithium nickel manganese cobalt (NMC) oxide cathode with graphite anodes have a 3.7 V nominal voltage with a 4.2 V max charge. The charging procedure is performed at constant voltage with current-limiting circuitry (i.e., charging with constant current until a voltage of 4.2 V is reached in the cell and continuing with a constant voltage applied until the current drops close to zero). Typically, the charge is terminated at 3% of the initial charge current. In the past, lithium-ion batteries could not be fast-charged and needed at least two hours to fully charge. Current-generation cells can be fully charged in 45 minutes or less. Some lithium-ion varieties can reach 90% in as little as 10 minutes.[41]

Charging procedure

Stage 1: Apply charging current limit until the voltage limit per cell is reached.[42]

Stage 2: Apply maximum voltage per cell limit until the current declines below 3% of rated charge current.[42]

Stage 3: Periodically apply a top-off charge about once per 500 hours.[42]

The charge time is about three to five hours, depending on the charger used. Generally, cell phone batteries can be charged at 1C and laptop-types at 0.8C, where C is the current that would discharge the battery in one hour. Charging is usually stopped when the current goes below 0.03C but it can be left indefinitely depending on desired charging time. Some fast chargers skip stage 2 and claim the battery is ready at 70% charge.[42] Laptop battery chargers sometimes gamble, and try to charge up to 4.35 V then disconnects the battery. This helps to compensate for the battery's internal resistance and charges up to 100% in short time.

Top-off charging is recommended when voltage goes below 4.05 V/cell.[42]

Lithium-ion cells are charged with 4.2 ± 0.05 V/cell, except for military long-life cells where 3.92 V is used for extending battery life. Most protection circuits cut off if either 4.3 V or 90 °C is reached. If the voltage drops below 2.50 V per cell, the battery protection circuit may also render it unchargeable with regular charging equipment. Most battery protection circuits stop at 2.7–3.0 V per cell.[42]

For safety reasons it is recommended the battery be kept at the manufacturer's stated voltage and current ratings during both charge and discharge cycles.

Variations in materials and construction

The increasing demand for batteries has led vendors and academics to focus on improving the power density, operating temperature, safety, durability, charging time, output power, and cost of LIB solutions.

| Area | Technology | Researchers | Target application | Date | Benefit |

|---|---|---|---|---|---|

| Cathode | Manganese spinel (LMO) | Lucky Goldstar Chemical,[43] NEC, Samsung,[44] Hitachi,[45] Nissan/AESC[46] | Hybrid electric vehicle, cell phone, laptop | 1996 | durability, cost |

| Lithium iron phosphate | University of Texas/Hydro-Québec,[47]/Phostech Lithium Inc., Valence Technology, A123Systems/MIT[48][49] | Segway Personal Transporter, power tools, aviation products, automotive hybrid systems, PHEV conversions | 1996 | moderate density (2 A·h outputs 70 amperes) operating temperature >60 °C (140 °F) | |

| Lithium nickel manganese cobalt (NMC) | Imara Corporation, Nissan Motor[50][51] | 2008 | density, output, safety | ||

| LMO/NMC | Sony, Sanyo | power, safety (although limited durability) | |||

| Lithium iron fluorine phosphate | University of Waterloo[52] | 2007 | durability, cost (replace Li with Na or Na/Li) | ||

| Lithium air | University of Dayton Research Institute[53] | automotive | 2009 | density, safety[53] | |

| 5% Vanadium-doped Lithium iron phosphate olivine | Binghamton University[54] | 2008 | output | ||

| Anode | Lithium-titanate battery (LT) | Altairnano | automotive (Phoenix Motorcars), electrical grid (PJM Interconnection Regional Transmission Organization control area,[55] United States Department of Defense[56]), bus (Proterra[57]) | 2008 | output, charging time, durability (20 years, 9,000 cycles), safety, operating temperature (-50–70 °C (-58–158 °F)[58] |

| Lithium vanadium oxide | Samsung/Subaru.[59] | automotive | 2007 | density (745Wh/l)[60] | |

| nano-sized wires from genetically modified virus | MIT | 2006 | density, thickness[61][62] | ||

| nano-sized wires on stainless steel | Stanford University | 2007 | density[63][64] (shift from anode- to cathode-limited), durability (wire cracking) | ||

| Metal hydrides | Laboratoire de Réactivité et de Chimie des Solides, General Motors | 2008 | density (1480 mA·h/g)[65] | ||

| Electrode | LT/LMO | Ener1/Delphi,[66][67] | 2006 | durability, safety (limited density) | |

| Nanostructure | Université Paul Sabatier/Université Picardie Jules Verne[68] | 2006 | density | ||

| Virus-based synthesis, gold-doping | MIT[69][70] | 2009 | density |

Usage guidelines

Prolonging battery pack life

- Depletion below the low-voltage threshold (2.4 to 2.8 V/cell, depending on chemistry) results in a dead battery because the protection circuit (a type of electronic fuse) disables it.[71] This can often be reversed in modern devices, especially single-cell devices, by re-applying a charging voltage for long enough that the cell voltage re-crosses the threshold; however this behaviour varies by manufacturer.

- Lithium-ion batteries should be kept cool. They may be stored in a refrigerator.[71]

- Lithium-ion batteries degrade much faster if stored in high-temperature areas.[71]

Multicell devices

Li-Ion batteries require a Battery Management System to prevent operation outside each cell's Safe Operating Area (over-charge, under-charge, safe temperature range) and to balance cells to eliminate SOC mismatches, significantly improving battery efficiency and increasing overall capacity.[72] As the number of cells and load currents increase, the potential for mismatch also increases.[73] There are two kinds of mismatch in the pack: state-of-charge (SOC) and capacity/energy ("C/E") mismatch. Though SOC is more common, each problem limits pack capacity (mA·h) to the capacity of the weakest cell.

Safety

Lithium-ion batteries can rupture, ignite, or explode when exposed to high temperature. Short-circuiting a battery will cause the cell to overheat and possibly to catch fire. Adjacent cells may also then heat up and fail, in some cases, causing the entire battery to ignite or rupture. In the event of a fire, the device may emit dense irritating smoke.[74]

Replacing the lithium cobalt oxide cathode material in lithium-ion batteries with a lithium metal phosphate such as lithium iron phosphate, improves cycle counts, shelf life and safety, but lowers capacity. Currently, these 'safer' lithium-ion batteries are mainly used in electric cars and other large-capacity battery applications, where safety issues are critical.[75]

Lithium-ion batteries normally contain safety devices to protect the cells from disturbance. However, contaminants inside the cells can defeat these safety devices.

Recalls

In March 2007, Lenovo recalled approximately 205,000 batteries at risk of explosion. In August 2007, Nokia recalled over 46 million batteries at risk of overheating and exploding.[76] One such incident occurred in the Philippines involving an Nokia N91, which uses the BL-5C battery.[77]

In December 2006, Dell recalled approximately 22,000 laptop batteries from the U.S. market.[78] Approximately 10 million Sony batteries used in Dell, Sony, Apple, Lenovo/IBM, Panasonic, Toshiba, Hitachi, Fujitsu and Sharp laptops were recalled in 2006. The batteries were found to be susceptible to internal contamination by metal particles. Under some circumstances, these particles could pierce the separator, causing a short-circuiting.[79]

In October 2004, Kyocera Wireless recalled approximately 1 million mobile phone batteries to identify counterfeits.[80]

Transport restrictions

In January 2008, the United States Department of Transportation ruled that passengers on board commercial aircraft could carry lithium batteries in their checked baggage if the batteries are installed in a device. Types of batteries affected by this rule are those containing lithium, including Li-ion, lithium polymer, and lithium cobalt oxide chemistries. Lithium-ion batteries containing more than 25 grams (0.88 oz) equivalent lithium content (ELC) are exempt from the rule and are forbidden in air travel.[81] This restriction greatly reduces the chances of the batteries short-circuiting and causing a fire.

Additionally, a limited number of replacement batteries may be transported in carry-on luggage. Such batteries must be sealed in their original protective packaging or in individual containers or plastic bags.[81][82]

Some postal administrations restricted air shipping (including EMS) of lithium and lithium-ion batteries, and products containing these (e.g. laptops, cell phones etc.). Among these countries are Hong Kong,[83] and Japan.[84]

See also

- Nanowire battery

Notes

- ↑ 1.0 1.1 1.2 1.3 1.4 "Rechargeable Li-Ion OEM Battery Products". Panasonic.com. http://www.panasonic.com/industrial/batteries-oem/oem/lithium-ion.aspx. Retrieved 2010-04-23.

- ↑ Valøen & Shoesmith (2007). The effect of PHEV and HEV duty cycles on battery and battery pack performance (PDF). 2007 Plug-in Highway Electric Vehicle Conference: Proceedings. Retrieved 2010-06-11.

- ↑ 11.10V,6600Mah, Li-Ion, Replacement Laptop Battery For Dell (etc). Amazon.com Online Store. Retrieved 2010-06-11.

- ↑ H. Abea, T. Muraia and K. Zaghibb (1999). Vapor-grown carbon fiber anode for cylindrical lithium ion rechargeable batteries. Journal of Power Sources 77:2, February 1999, pp. 110-115. DOI:10.1016/S0378-7753(98)00158-X. Retrieved 2010-06-11.

- ↑ Battery Types and Characteristics for HEV ThermoAnalytics, Inc., 2007. Retrieved 2010-06-11.

- ↑ Ballon, Massie Santos (14 October 2008). "Electrovaya, Tata Motors to make electric Indica". cleantech.com. Cleantech Group. http://www.cleantech.com/news/3694/electrovaya-tata-motors-make-electric-indica. Retrieved 2010-06-11.

- ↑ David Linden, Thomas B. Reddy (ed). Handbook Of Batteries 3rd Edition. McGraw-Hill, New York, 2002 ISBN 0-07-135978-8 chapter 35

- ↑ Silberberg, M. 2006. Chemistry: The Molecular Nature of Matter and Change, 4th Ed. New York (NY): McGraw-Hill Education. p 935.

- ↑ Thackeray, Thomas, and Whittingham (March 2000). Science and Applications of Mixed Conductors for Lithium Batteries. mrs.com; Materials Research Society. Retrieved 2010-06-11.

- ↑ MSDS: National Power Corp Lithium Ion Batteries (PDF). tek.com; Tektronix Inc., 7 May 2004. Retrieved 2010-06-11.

- ↑ M Stanley Whittingham. Electrical Energy Storage and Intercalation Chemistry Science: 192 (4244): 1126

- ↑ Yazami, R. and Touzain, Ph., International Meeting on Lithium Batteries, Rome, April 27–29, 1982, C.L.U.P. Ed. Milan, Abstract # 23

- ↑ Yazami, R.; Touzain, Ph. (1983). "A reversible graphite-lithium negative electrode for electrochemical generators". Journal of Power Sources 9 (3–4): 365–371. doi:10.1016/0378-7753(83)87040-2.

- ↑ US 4304825, Basu; Samar, "Rechargeable battery", issued 8 December 1981, assigned to Bell Telephone Laboratories

- ↑ USPTO search for inventions by "Goodenough, John"

- ↑ M.M. Thackeray, W.I.F. David, P.G. Bruce, and J.B. Goodenough (4 February 1983). "Lithium insertion into manganese spinels". Materials Research Bulletin (Elsevier) 18 (4): 461–472. doi:10.1016/0025-5408(83)90138-1.

- ↑ Gholamabbas Nazri, Gianfranco Pistoia (2004). Lithium batteries: science and ... - Google Books. Springer. http://books.google.com/?id=k4duxuea3eIC. Retrieved 2009-10-08.

- ↑ Voelcker, John (September 2007). Lithium Batteries Take to the Road IEEE Spectrum.

- ↑ A. Manthiram and J.B. Goodenough Corresponding (16 May 1989). "Lithium insertion into Fe2(SO4)3 frameworks". Journal of Power Sources (Elsevier B.V.) 26 (3-4): 403–408. doi:10.1016/0378-7753(89)80153-3.

- ↑ A.K. Padhi, K.S. Nanjundaswamy and J.B. Goodenough, J. (1997). "Phospho-olivines as positive-electrode materials for rechargeable lithium batteries". Electrochem. Society 144: 1188–1194. http://scitation.aip.org/getabs/servlet/GetabsServlet?prog=normal&id=JESOAN000144000004001188000001&idtype=cvips&gifs=yes.

- ↑ 21.0 21.1 Editors (6 March 2008). "In search of the perfect battery" (PDF). The Economist. Archived from the original on 2009-09-25. http://www.mitenergyclub.org/assets/2009/9/25/Economist_Batteries2008.pdf. Retrieved 2010-05-11.

- ↑ 22.0 22.1 22.2 22.3 Staff (November 2003) (PDF). Lithium Ion technical handbook. Gold Peak Industries Ltd.. http://www.gpbatteries.com/html/pdf/Li-ion_handbook.pdf.

- ↑ H.C. Choi et al., J. Phys. Chem. B 107 p5806(2003) doi:10.1021/jp030438w

- ↑ G.G. Amatucci, J.M. Tarascon, L.C. Kein J. Electrochemical Society 143 p1114 1996 doi:10.1149/1.1836594

- ↑ R. Ruffo; S. S. Hong, C. K. Chan, R. A. Huggins, Y. Cui (2009). "Impedance Analysis of Silicon Nanowire Lithium Ion Battery Anodes" (PDF). J. Phys. Chem. C. (113 (26), (2009)): 11390–11398. doi:10.1021/jp901594g. http://www.stanford.edu/group/cui_group/papers/Impedance_jpc.pdf. Retrieved 2009-09-01.

- ↑ C. K. Chan; X. F. Zhang, Y. Cui (2007). "High Capacity Li-ion Battery Anodes Using Ge Nanowires" (PDF). Nano Lett. (8 (2007)): 307–309. doi:10.1021/nl0727157. http://www.stanford.edu/group/cui_group/papers/High%20Capacity%20Li-ion%20Battery%20Anodes%20Using%20Ge%20Nanowires.pdf.

- ↑ Wenige, Niemann, et al. (May 30, 1998). Liquid Electrolyte Systems for Advanced Lithium Batteries (PDF). cheric.org; Chemical Engineering Research Information Center(KR). Retrieved 2010-06-11.

- ↑ Balbuena, P.B., Wang, Y.X., eds. Lithium Ion Batteries: Solid Electrolyte Interphase 2004 Imperial College Press, London

- ↑ Winter & Brodd 2004, p. 4256, 4258

- ↑ , Winter & Brodd 2004, p. 4254

- ↑ 31.0 31.1 31.2 Winter & Brodd 2004, p. 4259

- ↑ Aging - capacity loss BatteryUniversity.com.

- ↑ 33.0 33.1 Winter & Brodd 2004, p. 4258

- ↑ Altair Nano: Power & Energy Systems

- ↑ Battery University: Fig. 1 Non-recoverable capacity loss

- ↑ Buchmann, Isidor. "Choosing a battery that will last". Isidor Buchmann (CEO of Cadex Electronics Inc.). http://www.buchmann.ca/Article9-Page1.asp.

- ↑ Buchmann, Isidor (September 2006). "BatteryUniversity.com: How to prolong lithium-based batteries". Cadex Electronics Inc.. http://www.batteryuniversity.com/parttwo-34.htm.

- ↑ Spotnitz, R.; Franklin, J. (2003). "Abuse behavior of high-power, lithium-ion cells". Journal of Power Sources (Elsevier) 113: 81–100. doi:10.1016/S0378-7753(02)00488-3.

- ↑ Buchmann, Isidor (February 2003). "Advanced battery analyzers". Isidor Buchmann. http://www.batteryuniversity.com/parttwo-43.htm. Retrieved 2009-12-26.

- ↑ Lewis, Leo (21 August 2007). "Japanese experts demand change to make phones and laptops safe". London: The Times. http://business.timesonline.co.uk/tol/business/industry_sectors/technology/article2295743.ece.

- ↑ AeroVironment achieves electric vehicle fast-charge milestone avinc.com; AeroVironment, 30 May 2007. (Press release). "Test rapidly recharges a battery pack designed for use in passenger vehicles. 10-minute recharge restores enough energy to run electric vehicle for two hours at 60 miles per hour."

- ↑ 42.0 42.1 42.2 42.3 42.4 42.5 "Charging lithium-ion batteries". batteryuniversity.com. http://www.batteryuniversity.com/partone-12.htm. Retrieved 2009-05-21.

- ↑ Kevin Jost [ed.] (October 2006). Tech Briefs: CPI takes new direction on Li-ion batteries (PDF). aeionline.org; Automotive Engineering Online. Archived from the original. Retrieved 2010-06-11.

- ↑ Voelcker, John (September 2007). Lithium Batteries Take to the Road. IEEE Spectrum. Retrieved 2010-06-15.

- ↑ Loveday, Eric (23 April 2010). "Hitachi develops new manganese cathode, could double life of li-ion batteries". http://green.autoblog.com/2010/04/23/hitachi-develops-new-manganese-cathode-could-double-life-of-li/. Retrieved 2010-06-11..

- ↑ Nikkei (29 November 2009). Report: Nissan On Track with Nickel Manganese Cobalt Li-ion Cell for Deployment in 2015 Green Car Congress (blog). Retrieved 2010-06-11.

- ↑ Elder, Robert and Zehr, Dan (16 February 2006). Valence sued over UT patent Austin American-Statesman (courtesy Bickle & Brewer Law Firm). Archived from the original. Retrieved 2010-06-11.

- ↑ Bulkeley, William M. (26 November 2005). "New Type of Battery Offers Voltage Aplenty, at a Premium". The Day: p. E6. http://news.google.com/newspapers?id=fCAiAAAAIBAJ&pg=1148,5896335.

- ↑ A123Systems (2 November 2005). A123Systems Launches New Higher-Power, Faster Recharging Li-Ion Battery Systems Green Car Congress; A123Systems (Press release). Retrieved 2010-05-11.

- ↑ Imara Corporation website

- ↑ O'Dell, John (17 December 2008). Fledgling Battery Company Says Its Technology Boosts Hybrid Battery Performance Green Car Advisor; Edmunds Inc. Retrieved 2010-06-11.

- ↑ B. L. Ellis, W. R. M. Makahnouk, Y. Makimura, K. Toghill & L. F. Nazar (9 September 2007). "A multifunctional 3.5 V iron-based phosphate cathode for rechargeable batteries". Nature Materials. pp. 749–753. doi:10.1038/nmat2007. http://www.nature.com/nmat/journal/v6/n10/abs/nmat2007.html. Retrieved 2009-10-08.

- ↑ 53.0 53.1 "A Research First: Lithium Air Battery Development (Press Release)". 17 November 2009. http://www-ig.udayton.edu/News/Article/?contentId=25610. Retrieved 2010-06-11.

- ↑ Jian Hong, C. S. Wang, Shailesh Upreti and M. Stanley Whittinghama. "Vanadium Modified LiFePO4 Cathode for Li-ion Batteries". ECS (ETS) 12 (2): A33. http://link.aip.org/link/?ESLEF6/12/A33/1. Retrieved 2010-06-11.

- ↑ Altair Nanotechnologies (21 November 2008). "... Acceptance of the First Grid-Scale, Battery Energy Storage System". Press release. http://www.b2i.us/profiles/investor/ResLibraryView.asp?ResLibraryID=27574&GoTopage=1&BzID=546&Category=1183&a=. Retrieved 2009-10-08.

- ↑ Marty Ozols (11 November 2009). Altair Nanotechnologies Power Partner - The Military Systemagicmotives (personal webpage). Retrieved 2010-06-11.

- ↑ "Proterra Corporate website". Proterra. http://www.proterraonline.com/partners.asp. Retrieved 2009-10-08.

- ↑ Microsoft PowerPoint - 061125 Altair EDTA Presentation

- ↑ Blain, Loz (2 November 2007). "Subaru doubles the battery range on its electric car concept". gizmag. http://www.gizmag.com/go/8281/. Retrieved 2009-10-08.

- ↑ "Li-Ion Rechargeable Batteries Made Safer". Nikkei Electronics Asia. 29 January 2008. http://techon.nikkeibp.co.jp/article/HONSHI/20080129/146549/. Retrieved 2009-10-08.

- ↑ Ki Tae Nam, Dong-Wan Kim, et. al. (6 April 2006). Virus-Enabled Synthesis and Assembly of Nanowires for Lithium Ion Battery Electrodes. Science Express (preprint). Retrieved 2010-06-11.(subscription required)

- ↑ Palca, Joe (6 April 2009). Hidden Ingredient In New, Greener Battery: A Virus. npr.org; National Public Radio. Retrieved 2010-06-11.

- ↑ "New Nanowire Battery Holds 10 Times The Charge Of Existing Ones". sciencedaily.com. Science Daily. 20 December 2007. http://www.sciencedaily.com/releases/2007/12/071219103105.htm.

- ↑ Dennis, Lyle (21 December 2007). "Interview with Dr. Cui, Inventor of Silicon Nanowire Lithium-ion Battery Breakthrough". GM-Volt. http://www.gm-volt.com/2007/12/21/gm-voltcom-interview-with-dr-cui-inventor-of-silicon-nanowire-lithium-ion-battery-breakthrough. Retrieved 2009-10-08.

- ↑ Y. Oumellal, A. Rougier, G. A. Nazri, J-M. Tarascon & L. Aymard (12 October 2008). "Metal hydrides for lithium-ion batteries". Nature Materials 7: 916–921. http://www.nature.com/nmat/journal/v7/n11/abs/nmat2288.html. Retrieved 2009-10-08.

- ↑ Welcome to Ener1. Ener1 (Press release). Archived from the original 2006-07-08. Retrieved 2010-06-11.

- ↑ EnerDel Technical Presentation (PDF). EnerDel Corporation. 29 October 2007. Archived from the original. Retrieved 2010-06-11.

- ↑ Bullis, Kevin (22 June 2006). Higher-Capacity Lithium-Ion Batteries Technology Review. Retrieved 2010-06-11.

- ↑ Zandonella, Catherine (11 April 2009). "Battery grown from "armour plated" viruses". New Scientist (Tribune media Services International) 202 (2703): 1. http://www.newscientist.com/article/mg20227035.400-batteries-grown-from-armourplated-viruses.html.

- ↑ Bullis, Kevin (28 September 2006). "Powerful Batteries That Assemble Themselves". technologyreview.com. Technology Review. http://www.technologyreview.com/energy/17553/?a=f. Retrieved 2010-06-15.

- ↑ 71.0 71.1 71.2 http://batteryuniversity.com/parttwo-34.htm

- ↑ Andrea, Davide (21 August 2008). About Battery Management Systems. ELithion LLC. Retrieved 2010-06-15.

- ↑ Andrea, Davide (19 September 2008). White Paper - CCCV chargers: a false sense of security. ELithion LLC. Retrieved 2010-06-15.

- ↑ [|Electrochem Commercial Power] (9 September 2006). "Safety and handling guidelines for Electrochem Lithium Batteries" (PDF). marine.rutgers.edu. Rutgers University. http://marine.rutgers.edu/~haldeman/Instruments/lithium_safety/Electrochem_Lithium_safety_15-SAF-0043.pdf. Retrieved 2009-05-21.

- ↑ Cringely, Robert X. (1 September 2006). "Safety Last". The New York Times. http://www.nytimes.com/2006/09/01/opinion/01cringely.html. Retrieved 2010-04-14.

- ↑ Nokia issues BL-5C battery warning, offers replacement. Wikinews. 14 August 2007. http://en.wikinews.org/wiki/Nokia_issues_BL-5C_battery_warning%2C_offers_replacement. Retrieved 2009-10-08.

- ↑ Staff (27 July 2007). Nokia N91 cell phone explodes Mukamo - Filipino News (blog). Retrieved 2010-06-15.

- ↑ Tullo, Alex. (21 August 2006). "Dell Recalls Lithium Batteries". Chemical and Engineering News:11; American Chemical Society. Retrieved 2010-06-15.

- ↑ Hales, Paul (21 June 2006). Dell laptop explodes at Japanese conference. The Inquirer. Retrieved 2010-06-15.

- ↑ Kyocera Wireless (28 October 2004). "Kyocera Launches Precautionary Battery Recall, Pursues Supplier of Counterfeit Batteries". Press release. Archived from the original on 7 January 2006. http://web.archive.org/web/20060107210116/http://www.kyocera-wireless.com/news/20041028_2.htm. Retrieved 2010-06-15.

- ↑ 81.0 81.1 "Safe Travel". Safetravel.dot.gov. U.S. Department of Transportation. 1 January 2008. http://safetravel.dot.gov/whats_new_batteries.html. Retrieved 2009-10-08.

- ↑ Galbraith, Rob (3 January 2008). "U.S. Department of Transportation revises lithium battery rules press release". Little Guy Media. http://www.robgalbraith.com/bins/content_page.asp?cid=7-9206-9211. Retrieved 2009-05-11.

- ↑ Prohibitions - 6.3.12 - Dangerous, offensive and indecent articles (PDF). Hong Kong Post Office Guide. December 2009. Retrieved 2010-06-15.

- ↑ International Mail > FAQs > Goods/Services: Shipping a Laptop Japan Post Service Co. Ltd. Retrieved 2010-06-15.

References

- Winter, M.; Brodd, J. (2004). "What Are Batteries, Fuel Cells, and Supercapacitors?" (PDF). Chemical Review 104 (104): 4245. doi:10.1021/cr020730k. http://pubs.acs.org/doi/pdf/10.1021/cr020730k. Retrieved 2010-07-25.

External links

- Lithium batteries at the Open Directory Project

- Argonne opens chapter in battery research -- lithium air. Argonne National Labs. Press release. 14 September 2009.

- Battery and Energy Technologies - Rechargeable Lithium batteries. Electropaedia; Woodbank Communications Ltd. Updated 28 April 2010.

- Stanford's nanowire battery holds 10 times the charge of existing ones. Stanford Report, 18 December 2007. Press release.

- The Lithium Ion Battery. E-Articles.com. (Self-publishing site).

- The Future of Electric Vehicles: Setting the Record Straight on Lithium Availability. Journal of Energy Security, 27 August 2009. Keith Evans.

|

||||||||||||||||